Special Application Gauges

What is a Special Application?

Process for ordering a special application gauge:

The process for a Sangha special gauge is very simple. In the first instance, email us or call us to discuss your requirement. Then we will ask you to send us a drawing of the measurement problem. Or, where practical, send us the actual part on which the measurement is required (though a drawing will normally suffice). From the drawing (or the part), we can send you a detailed quotation for your approval. Then, our normal lead times are two to four weeks depending on the complexity of the project. Our special applications are delivered worldwide, and location is not an issue. Our special applications are a cost-effective way to improve your factory processes and speed up your production with accuracy and convenience.

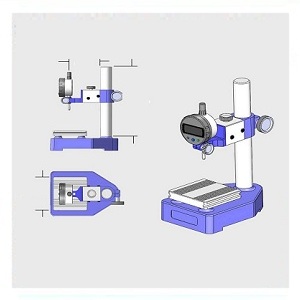

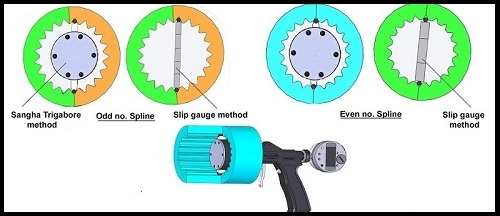

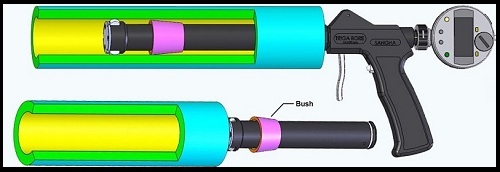

Spline Measurement Gauge

A simple, efficient and cost effective way to measure the best wire pitch diameter of splines. This is an easy-to-use and very ergonomic pistol grip (or level grip) instrument that is a great alternative to the slip gauge and wire method.

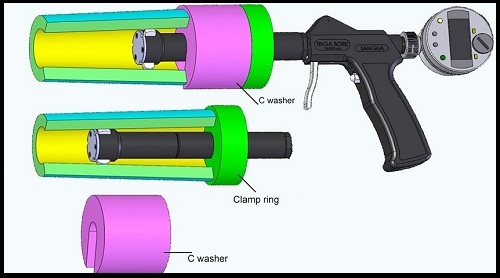

Taper Measurement Gauge

Available with different contact points including spherical and blind bore, the Sangha Taper Gauge provides an efficient and accurate was to measure tapers.

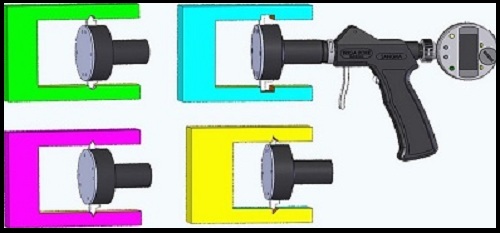

Slot Measurement Gauge

Ergonomic and able to measure hard to reach places. The Sangha Slot Measurement Gauge is an efficient and cost effective way to measure difficult to measure slots. Custom built to individual requirements.

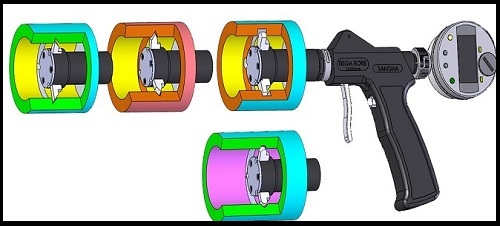

Thread Measurement System

A quick and efficient way to measure pitch diameters of threads, here is a simple and cost effective alternative to more traditional (and time consuming) methods. Build to individual specifications, here is a great way to streamline shop floor thread measurement.

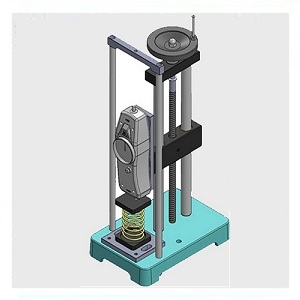

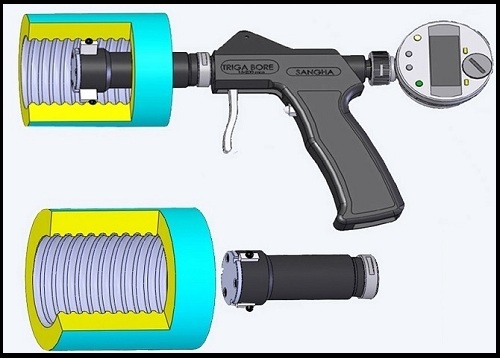

Ball Screw Measurement System

Often considered a difficult to measure problem, Sangha have developed an innovative and efficient way to accurately measure ball nut screws. Made to your exact requirements,this is by far the simplest and most cost-effective method.

Deep Hole Measurement Gauge

Used extensively in the oil and gas industry, this is an ergonomic and easy-to-use deep hold measuring system. The depth can be any length (our longest to date has been 30 metres but it can be any length necessary).

'O' Ring Groove Measurement Gauge

O-ring grooves are notoriously difficult to measure,especially when in a difficult to reach location. Our simple measuring system enables you to specify your exact requirements and save time and money in the process.

Spherical Diameter Measurement

Often a difficult problem to solve, this clever solution will enable shop floor operatives to easily and quickly measure problematic spherical diameters.

Sangha Metrology Locations

UK and Europe

Blanche Street Bradford

BD4 8DA ENGLAND

Telephone:0044(O)7708967805

team@sanghametrology.com

India and Asia

Euro Design Services (EDS)

Exclusive Manufacturer and

and distributor of

Sangha Metrology (UK)

WhatsApp:00919876052433

America

Flexbar Machine Corporation

Islandia,New York

team@sanghametrology.com

Australia

team@sanghametrology.com

CONTACT US FOR ANY QUESTIONS