“Introducing the New Sangha Taper Measuring Gauge” For a time-served engineer working on a factory floor, difficult processes and procedures become easy and quick over time. But, you have to acquire that experience and absorb that knowledge after many years (usually after one or two costly mistakes!) Of course “the old ways” have worked well for generations, but innovations in practice and procedure are not to be sneered at. Engineers, of all people, should be willing to accept change, new technology and updated methods for conquering problems. A case in point is the introduction of the Sangha Taper Measuring Gauge. This innovation came about when Sangha, a company with 30 years experience in the field of metrology, were approached by a client that was struggling with errors coming from the inaccurate measurement of internal tapers on the factory floor, resulting in lost time and money.

The problems the client was facing was down to operator error or lack of experience on the part of an un-skilled or semi-skilled technician. So, with the task of solving this problem, Sangha set about developing a nifty and simple-to-learn device that has already saved industry countless shop floor hours and money. The Sangha Taper Gauge has taken the old method of taper measurement and streamlined it to the point where two measurements on a taper are all that need measuring. An ultra-easy technique that can be taught to a new operator within minutes (be they skilled or un-skilled) and will bring you to an accurate measurement with repeatable results in a fraction of the time as other methods.

The Sangha Taper Gauge has been proven to save teaching time, save time lost in errors, and save time in the long run by replacing a traditional practice with a modern solution. Traditional taper measurement is difficult (at least to all but the most technical among us.) And quite frankly, even technical people would probably prefer a quicker method if it delivered the same results. The process of measuring tapers on most shop floors would usually look something like this: 1) Measure ball bearings using a caliper or a micrometer (which in itself can be tricky for the un-initiated or less dexterous.) 2) Insert ball bearings into the bore. 3) Then the opreator has to find the height of the bore, which is simple enough if it can be easily reached (though not so simple otherwise.) So already you have used two or three different devices, trying to locate a number of different figures. 4) Then the operator has to calculate the taper, which is only accurate if the previous steps are correct. As you can see, internal taper measurement using traditional (dare we say it “old fashioned”) techniques can be a time consuming and laborious task, with considerable scope for error if the various steps are not done properly.

Not that traditional engineering skill is irrelevant, absolutely not! All apprentices and operators, and graduates of engineering, should know how to measure taper diameters using traditional means…forming a solid basis for theory and knowledge. But in practice there are better, faster, more efficient techniques that will serve industry greatly through the smart adoption of improved technology.

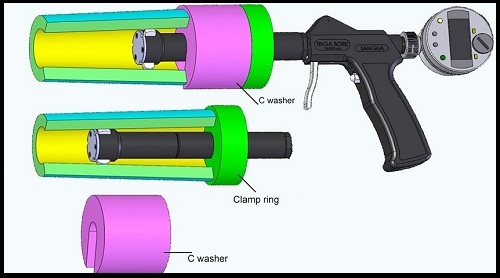

Returning to the Sangha Taper Gauge, this method replaces the tricky part of taper measurement by using one single easy to hold instrument which is ergonomic, light weight, and can be used with one hand! It is simple to learn and reduces the need for time consuming interpretation and calculation. It replaces several other devices (such as ball bearings, calipers and micrometers, with one streamlined gauge. And, it is quick, simple, efficient, sturdy, hard wearing and will last forever under even the toughest of factory conditions. This clever gauges is born of real-world industry experience and solves a real problem that many shop floor operators face on a daily basis. Sangha hope that by adopting newer, efficient and more streamlined approaches to measuring internal tapers, that industry will be better placed to use time more effectively and with greater ease and efficiency. What’s more, Sangha have perfected a fast approach to bespoke taper gauge design and manufacture, which means all Sangha gauges can be custom built to a client’s individual requirements.

For more details about this new system to measure tapers, please contact Sangha at team@sanghametrology.com or call 0044 (0) 07708967805 or WATSAPP 0044 (0) 777 276 7072. To see the extensive range of Sangha Metrology instruments, all of which are designed to save your company time and money, please visit www.sanghametrology.com.

For more details please visit www.sanghametrology.com

Introducing the New Sangha Taper Measuring Gauge

19

Feb